Overview

Intelligent system of production line with RFID technology real-time collective the production data in the process of production, quality parameters, equipment status, and statistics and analysis, so to improve the product's rty and equipment utilization rate. The production line has great flexibility, can meet the needs of the many kinds of production.

Solution

Delto DLT - ZNCX8000 Intelligent system of production line adopte PLC and modern bus network communication of modern mature, control intelligent production line manufacturing process of all kinds of equipment for, read automatically pallet RFID tag in the process of production equipment, collect air-conditioning data in the process of production, improve the working efficiency of the operators and equipment, the unit product consumption of working hours, reduce costs (equivalent to increase the per capita output), reduce the wip process, truly a "flow", in unit based on the production line of the balance of production, improve production strain capacity, corresponding to the market changes, realize flexible manufacturing system, through the analysis of comprehensive balance production line can be applied to the program (Layout) analysis, movement analysis, planning, handling all IE techniques such as analysis, time analysis, improve the comprehensive quality of the whole.

Functions and features

1) Intelligent analysis and design of database

2) Intelligence backup and restore of database

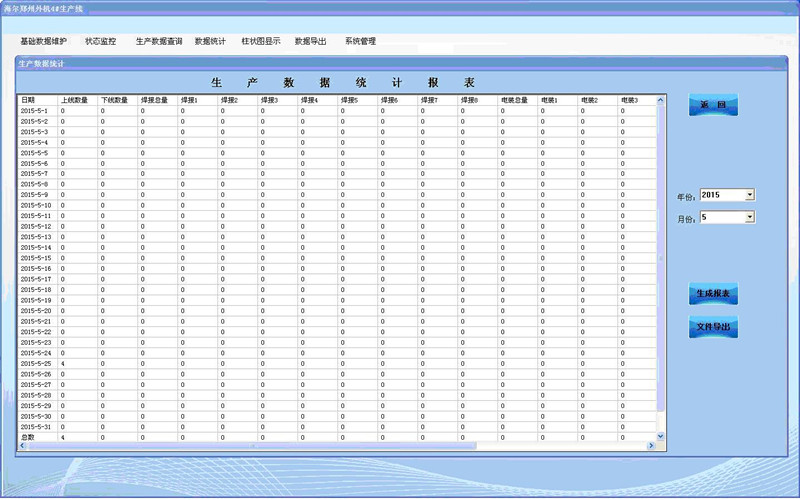

3) Production data acquisition and control in real time

4) Product drawings issued by process control

5) Real-time information display and control

6) Integration of real-time monitoring machine and touch screen

7) RFID wireless communication interface

8) Production data can be able to query, display and export

9) Data exchange with MES system